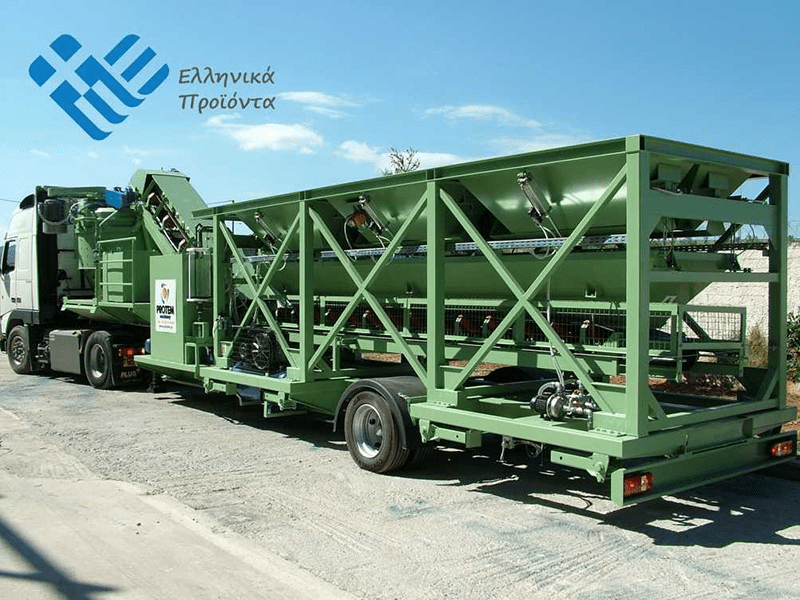

The PR-M 50 has the shape of a low bed single axle semi-trailer. A normal tractor, which most construction companies use for the transportation of aggregates, can be used to transport the machine.

When arriving at site, due to the build-in air suspension, the semi-trailer can be lifted (approx. 10 cm) helping the driver not only easily releasing the tractor from the trailer but also deploying in working position the supporting legs of the machine.

There is no special need for civil works at site, except of a concrete deck (approx. 13x4m) with a bearing capacity of 2.5 kg/cm2 at the point where the batching plant will operate.

A small ramp is also necessary for feeding the aggregates bins when the optional ground level feeding and distribution system is not presented.

The PR-M 50 has the shape of a low bed single axle semi-trailer. A normal tractor, which most construction companies use for the transportation of aggregates, can be used to transport the machine.

When arriving at site, due to the build-in air suspension, the semi-trailer can be lifted (approx. 10 cm) helping the driver not only easily releasing the tractor from the trailer but also deploying in working position the supporting legs of the machine.

There is no special need for civil works at site, except of a concrete deck (approx. 13x4m) with a bearing capacity of 2.5 kg/cm2 at the point where the batching plant will operate.

A small ramp is also necessary for feeding the aggregates bins when the optional ground level feeding and distribution system is not presented.

TECHNICAL CHARACTERISTICS

|

Specification

|

Unit

|

|

Compacted Concrete Output

|

40 m3/h

|

|

Planetary mixer capacity (compacted)

|

1 m3

|

|

Mixer Motor Power

|

50 Hp

|

|

No of Aggregate Compartments

|

3

|

|

Total Aggregates Compartments Capacity

|

3 X 20 =60 m3

|

|

Aggregates scale Capacity

|

5000 Kg

|

|

Cement scale Capacity

|

500 Kg

|

|

Electronic water meter with electro pneumatic ball valve

|

2"

|

|

Admixtures Weighing Capacity

|

40 Lt

|

|

Admixture loading pumps

|

2

|

|

Cement Screw Conveyor (Silo to scale)

|

Ø193/6000mm

|

|

Cement Screw Conveyor (Scale to mixer)

|

Ø223/5500mm

|

|

Cement Silo

|

Not included

|

|

Air compressor

|

4 kw /300 lt

|

|

Automation Control system

|

AUTO-LEADER 3000 P

|

|

Total Length / Width (Without Tractor)

|

13,5m / 2,55m

|

|

Maximum Height During Transportation

|

3,90m

|

|

Maximum Height During Operation

|

4,80m

|

|

Gross Weight

|

18.000kg

|

|

Total installed Power

|

78KW

|

|

Cerification

|

CE

|

|

Moisture Sensors

|

Optional

|

|

Concrete Conveying system (to Mixer Truck)

|

Optional

|

|

Aggregates bins feeding & Distribution System

|

Optional

|

ERECTION AND PRODUCTION START

The aggregates bins are foldable, thus they are assembled and put in operating position with the help of a wheel loader (always available at any construction site). The panels remain in operating position by special pins and additional bolts and nuts.

With the wheel loader the installer takes also the cement screw conveyor from its storage/transportation position and connects it to the output flange of the cement silo. The screw conveyor motor is pre-wired and has a waterproof electric socket for easily connection to the plant's electric board.

The plant’s water tank has to be connected with the external water supply. The same goes for the additives pumps with the external additive tanks or barrels.

Having finished the above works, it remains the filling of the aggregates bins and the power supply in order to start the production.

The operation of the plant is fully automatic with the use of a small console which is placed inside a waterproof case. The console is always connected to the electrical board located in the trailer’s side frame. With its extra-long cable the console can be moved in to an external cabin (control room) allowing the operator to operate the plant remotely.

A) Aggregates bins ground level feeding & Distribution System

It is a very useful system when the customer wants to avoid any civil works for the loading of the aggregates bunkers.

The system consists of:

- An Aggregate’s hopper with 15m3 capacity, which is installed on the ground level. The aggregates are loaded with a front loader to this hopper and then being transferred with the belt to the plant bunkers. A protection grill on the top of the aggregate’s hopper avoids the entrance of oversized aggregates, small rocks or any other unwanted objects.

- An inclined and horizontally rotating conveyor belt based on wheels, which transfers and distributes each material to the relevant aggregate’s bin compartment (bunkers).

- An automation control system

The system is delivered separately in a 40 ft container or an open truck

B) U type special concrete screw conveyor with inlet hopper

It is a very useful system when the batching plant is placed in the ground level and the concrete is coming out from the mixer has to be loaded in mixer trucks. The screw conveyor is placed under the mixer’s discharge gate and the concrete is uploaded to an inlet hopper that is acting as buffer.

Main system‘s characteristics

- Screw type: U (open) with detachable cover

- Overall length: 7.5 m

- Angle of operation: 40 0

- Discharge height: ~ 4.0 m

- Diameter: Inner Ø 300 mm

- Capacity: 30-35 m3/h fresh concrete

- Lining: impeller Hardox 500, walls Hardox 400

- Drive: 15 Kw gearmotor

- Inlet: Hopper capacity of ~ 500lt

- Outlet: Hose Ø 300

The screw is delivered separately in an open truck

C) Vertical Cement Silos

Paneled type cement silos 50 m3 (70 ton) with ladder (common ladder per two silos), safety rails on top, connection gangway for the 2 silos, butterfly valve Ø300. Preparation for future installation of dedusting filter, safety valve and level indicators.

The main characteristic of these silos is to be easily transported in several units on to one container, with considerable save of money. Erection on site is made very simple thanks to the manufacturing accuracy and the supply of installation manual.

Couplings between panels are water-proof thank to a special gasket which is supplied with every unit. High-quality galvanized bolts are included

D) Horizontal Cement Silos

Our horizontal silos are the ideal completion for the full mobile concrete mixing plant. They are extremely versatile, manageable and movable. You don’t need any authorization for the installation because there is no need of building works, it is sufficient to have a flat ground adequately solid.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back