- Detailed presentation

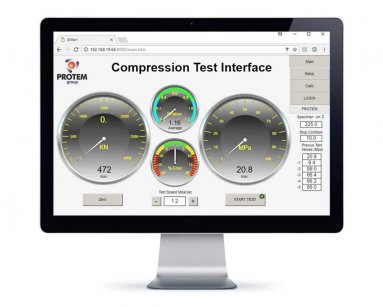

The compression testing machines are very simple to use and allow even inexperienced operators to perform the tests very easily. All settings, handling and tests are done through the web based SCADA software that is built into each machine and does not need to be installed on a computer.

All you need to do is connect the electronic control unit to a router or your company's network. After this, a user can operate the press through a PC or laptop, a tablet or even a smart phone provided that all of the above devices are connected to the network.

Each machine consists of the following:

- Four column heavy duty loading frame.

- Hydraulic power pack

- Hydraulic cylinder equipped with safety limit switch

- Upper platen Φ300 mm with self-adjusting ball seating assembly

- Lower platen Φ300 mm

- Distance pieces Φ 205x25 mm, Φ 205x50 mm and Φ 205x80 mm

- Front and rear protective safety doors. Front door has a safety limit switch.

- Electronic control unit

- Standard, web based SCADA software

The compression testing machines are very simple to use and allow even inexperienced operators to perform the tests very easily. All settings, handling and tests are done through the web based SCADA software that is built into each machine and does not need to be installed on a computer.

All you need to do is connect the electronic control unit to a router or your company's network. After this, a user can operate the press through a PC or laptop, a tablet or even a smart phone provided that all of the above devices are connected to the network.

Each machine consists of the following:

- Four column heavy duty loading frame.

- Hydraulic power pack

- Hydraulic cylinder equipped with safety limit switch

- Upper platen Φ300 mm with self-adjusting ball seating assembly

- Lower platen Φ300 mm

- Distance pieces Φ 205x25 mm, Φ 205x50 mm and Φ 205x80 mm

- Front and rear protective safety doors. Front door has a safety limit switch.

- Electronic control unit

- Standard, web based SCADA software

The four column loading frame provides the stability required for accurate and repeatable test results over many years of operation. The frame rigidity is 3.000 KN/mm.

- 30 liter oil tank with level and temperature indication.

- Two-stage oil pump inside the tank consisting of a) Low pressure gear pump b) High pressure radial piston pump. Thanks to the two-stroke pump the time until the specimen reaches the upper plate is reduced and accordingly the total duration of each test. The high-pressure pump’s revolutions are adjusted by an inverter accordingly to the desired rate of loading.

- The maximum operating pressure is 400 bar, which is the activation limit of the safety valve.

- The motor power of the pump is 380V / 50hz / 0.75Kw.

- The system also has an external oil filter that collects any particulates inside the circuit.

Hydraulic cylinder with a diameter of Ø250 for the 2.000KN press and Φ320 mm for the 3.000 ΚΝ and 4.000 ΚΝ presses with an active stroke of 50 mm.

A safety limit switch stops the operation of the press in case the piston tends to move out of bounds. In combination with the overpressure valve in the hydraulic pack, maximum safety is provided for the machine and its operator.

PLATENS AND SPACING BLOCKS

Upper plate Φ300 mm Χ 50mm self-leveling, according to EN 12390-4 , of high quality steel with roughness of 3.2μm, average hardness of 55 HRC and a flatness of ≤ 5μm

Bottom plate with the same features as the upper plate and additionally engraved concentric circles for easy specimen alignment.

Each press is equipped with standard spacing blocks Φ 205 x 25 mm, Φ 205 x 50 mm and Φ 205 x 80 mm.

The control unit of the press includes:

- Telemecanique PLC with PROTEM special PID software to automatically adjust the rate of loading.

- High accuracy pressure transducer 0,05% FS made by the Swiss company KELLER. This is a digital sensor that communicates with the PLC via RS485, bypassing the usage of analog converters (A/D) that usually distort the measurements.

- The sensor measures the ambient as well as the oil temperature, and automatically compensates for temperature variations providing the same accuracy in any ambient temperature conditions.

- Telemecanique or Fuji inverter. The rate of loading is controlled by changing the pump motor rotation speed.

- PROTEM’s SCADA software for monitoring and controlling the machine, specimen crushing and calibration. No installation required because it is a web application running through the browser on any device (PC, laptop, Tablet).

- Plug & Play ready to be connected to PROTEM’s optional Laboratory Management Software, Betolink® Laboratory.

The machines are very simple to use and allow even unexperienced operators to perform the tests very easily and without mistakes.

As soon as the specimen is placed and centered with the aid of the centering lines, the only required actions are:

- Selection of specimen type and rate of loading through the software (if these parameters are different from the standard).

- Pressing the START button on the screen or on the machine’s front panel. If the front door is not closed the test does not start.

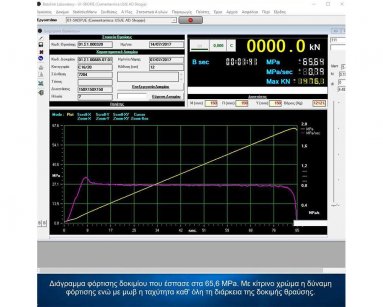

- The machine automatically starts a rapid approach until the specimen touches the upper plate and then begins to load the specimen at the selected rate (loading speed) and stops when the specimen breaks. During loading process, the machine automatically maintains the charging speed within the limits required by EN 12390-4. The screen shows the maximum loading force in KN, the corresponding Mpa value and the average loading rate in Mpa/sec.

- When the Betolink® Laboratory software is in place, the whole operation is completed through this software, while the charging diagram (crushing protocol) is also recorded.

The calibration of the press is also a very easy procedure through our built-in calibration Software routine.

- The hydraulic power pack together with the electronic control unit is not integrated into the press frame. It is an independent module and only requires the connection of the piston through a high pressure hose (included in the equipment), a 220V/10A main supply and an Ethernet connection.

- The press operates at extremely low noise levels (<60 dB).

- It does not require any special maintenance. The access at all points for inspection or repair is very easy.

- Each press is delivered pre-calibrated and ready for the official calibration, as defined by the regulation which states it must be done at the final installation place.

- Each press is accompanied by operation manual and installation instructions in English and Greek.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back