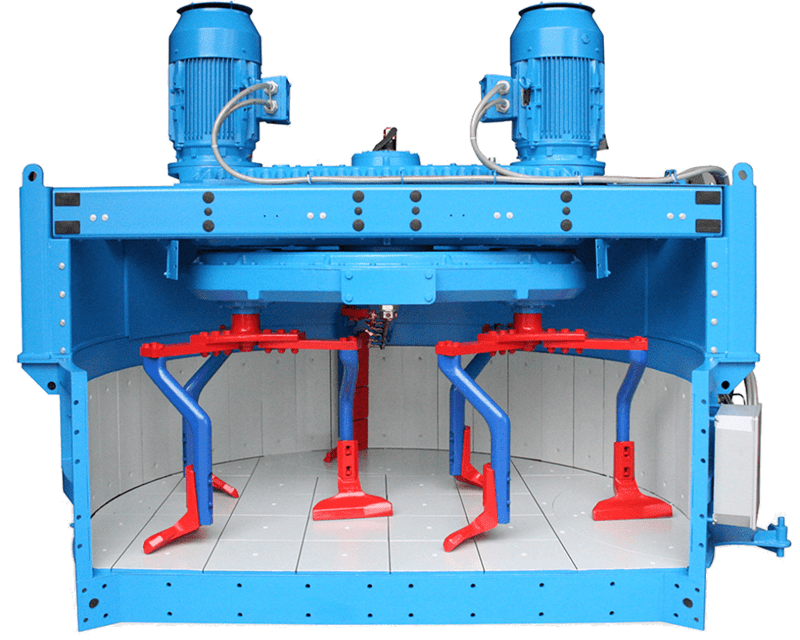

Vertical shaft mixers, also commonly known as planetary mixers, are best suited for mixing high quality concrete for cement products, prefabricated concrete and mortars. They achieve greater homogenization in a shorter time of mixing because of the satellite movement of its mixing blades. They clean and discharge very well while they are also ideal for colored concrete products. Planetary mixers have multiple discharge doors (up to four for certain models). Due to their low height they are also preferable for mobile concrete plants.

Planetary Mixers

PROTEM has for many years been an official partner of OMG (Officine Meccaniche Galletti Srl). We have installed many planetary mixers in our own manufactured batching plants and can safely say that they have one of the best price performance value on the market. At the same time, their credibility has been proven to our company and their spare parts or consumables are always available.

PROTEM has for many years been an official partner of OMG (Officine Meccaniche Galletti Srl). We have installed many planetary mixers in our own manufactured batching plants and can safely say that they have one of the best price performance value on the market. At the same time, their credibility has been proven to our company and their spare parts or consumables are always available.

OPERATING PRINCIPLE

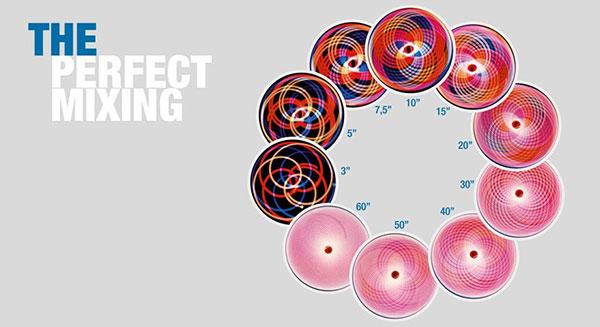

The planetary (or countercurrent) design has one or two mixing stars that rotate themselves while also rotating around a central point, allowing each arm to cover the whole mixer floor in a number of revolutions. This powerful mixing action is both fast and thorough, results in a mixing time, after water is added, of 30 seconds or less for most types of concrete. The floor is completely swept by the countercurrent action every 4 revolutions (10 seconds).

The result is greater throughput, providing more concrete per hour for the same size plant, as well as better consistency and greater strength or, on the other hand, a saving on cement. Galletti’s planetary design is superior to turbine and twin-shaft designs for production of all types of dry-cast concrete. The reason for this is its intense mixing action, which breaks up zero-slump mix quickly.

This animation shows the perfect mixing action of the planetary mixer from 3 to 60 seconds after material is added.

SPECIFICATIONS

Gearboxes

With 70 years of experience in engineering, OMG has created a gearbox that is almost indestructible. The huge double horizontal design is strong and shock resistant. The wide horizontal oil bath is cool running and gives every gear optimum lubrication. It is good for life and carries a 5 year, 10,000 hour warranty.

Mixing components

The mixing blades are made of Ni-Hard cast iron with a minimum hardness of 550HB, for excellent wear resistance. Outer edges are thickened to equalize wear and the angle of attack is optimized to push, not slice, to maximize both mixing and blade life.

The mixing arms are designed to avoid material accumulation and are made of spheroidal cast iron. Three arms per star, two stars starting from MP 1875/1250 and three starts from MP 4500/3000 and MP 6000/4000. Together with two hardened steel scraping arms they are the best for toughness plus abrasion resistance. Adjustment slots allow easy blade adjustment to compensate for wear.

The mixing tank is lined with normal steel plates or optionally 15 mm Ni-hard cast iron tiles that give many times the life of abrasion resistant steel liner plates, reducing lifetime cost. Bolted assembly makes replacement a simple task; in addition, the wall plates are reversible to increase life even further. Additionally, tight fabrication tolerances mean that blades can be adjusted close to walls and floor for perfect cleanout between batches, ensuring the best performance on colored products.

Discharge

Up to four swing-out sector doors running in rubber seals are completely watertight, non-jamming and low in maintenance, further reducing lifetime cost. Larger models are hydraulically powered while small models have choice of pneumatic or manual operation.

Mixer’s Cover

Half-moon door with widest opening of any, to give faster cleanup and adjustment of wear parts while making the process safer all round. One, two or three-part depending on mixer size. Single piece cover with hydraulic lift for easiest access is optional in largest models.

Junction Box

All connections, including motor 3-phase power as well as solenoid valves and switches, are available in one easy access junction box.

AVAILABLE MODELS

The planetary mixer MP series of OMG consist of the following available models:

| Model | Compacted Concrete output per circle | Nr. of satelites | Motor Power (kW) |

|---|---|---|---|

| MP 750 / 500 | 0,5 m3 | 1 | 1 x 18,5 |

| MP 1125 / 750 | 0,75 m3 | 1 | 1 x 30 |

| MP 1500 / 1000 | 1,0 m3 | 1 | 1 x 45 |

| MP 1875 / 1250 | 1,25 m3 | 2 | 1 x 55 |

| MP 2250 / 1500 | 1,5 m3 | 2 | 2 x 30 |

| MP 3000 / 2000 | 2,0 m3 | 2 | 2 x 45 |

| MP 3750 / 2500 | 2,5 m3 | 2 | 2 x 45 |

| MP 4500 / 3000 | 3,0 m3 | 3 | 3 x 45 |

| MP 6000 / 4000 | 4,0 m3 | 3 | 3 x 55 |

Each model can be optionally supplied with an integrated SKIP HOIST. The hoist has two grooved drums on the same shaft. The skip cable has an anti-free-fall block in case of cable failure while two limit switches constantly check its tension. Upon request, the double speed for ascent and descent is available.

OPTIONAL EQUIPMENT

Cement and aggregate inlets

Optimal introduction of cementitious ingredients can occur from either side of the mixer, so as to avoid the rotating planetary gearbox, and in the center of the access cover on some larger models. Aggregates are introduced at the side opposite to the access cover, through a chute or the optional skip hoist.

Cement and water scales

All MP series mixers can be equipped with weighing tanks for cement and water. They are delivered fixed to the body of the mixer and pre-assembled to minimize installation time on site.

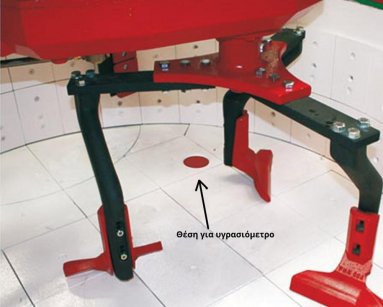

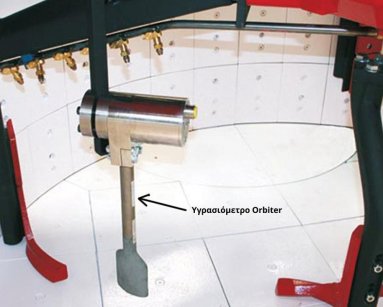

Moisture control

The production of high quality concrete usually requires moisture measurement in the mixer to control the water content of the mix. Due to the hollow main shaft (unique feature of OMG Gearbox), MP Mixers can be equipped with a moisture probe which is fixed to the scraping arm and rotating into the mixture (Hydro Orbiter). The probe cables are connected to the control system through a rotating collector.

Floor mounted moisture probe (HYDRO MIX) can also be installed at the floor level. In this case, perhaps the most important thing is to know whether you need the moisture meter or not at the start of the order. A hole can be opened at the mixer’s floor so a moisture meter can be installed in the future.

Sampling Box

All planetary mixers can be equipped with a sampling box for material sampling prior to discharge, usually used to prepare specimens. The operator can collect the sample very easily and safely without stopping the mixer and opening the top cover.

Water entry

The semicircular water spray bar is standard on models MP1875 and larger (extra cost on smaller models). It gives optimum distribution of water for all types of concrete; dry cast in particular. It is important to charge the water within 15 seconds for fastest mixing action, and this system is designed for the job. If feeding from a tank, a pump may be necessary to reach the right speed. Note the anti-siphon U-tubes that cut off water feed instantly; this is important when using a moisture control system.

FIELDS OF APPLICATION

- Precast, block, pavers, prefabricated concrete pipes or reinforced concrete.

- Glass and ceramic products.

- Production of dry mortars.

- Ready mixed concrete

- Refractory materials for foundry and chemical products

Open to new challenges

Do you have any idea of cooperation, you believe that our know-how can be adapted to your own field?

Do you have a special project and are looking for suitable partners to implement it? We are open to new opportunities...

Connect with us

Do you prefer live communication? So do we!

We'd love to speak with you.

Contact us

Get support

Do you have any technical questions?

Our experienced engineers will gladly discuss with you.

Technical Support

Stay updated

Are you interested in receiving updates

about our new products and offers?

Subscribe

Protem Group S.A.

3, 35th Str., 133 41 Industrial Park

Ano Liossia / Athens, Greece

info@protem.gr

Τ. +30 210 5716500

F. +30 210 5710008

GCR No: 7633901000

The Company

Contact

Company News

Legal Information

1989 - 2024

Φέτος έχουμε γενέθλια! Τον Ιούλιο κλείνουμε τα 35!

35 χρόνια σκληρή δουλειά με αγάπη, αφοσίωση και με σημαντικές επιτυχίες! 35 δημιουργικά χρόνια. Θα τα γιορτάζουμε μαζί σας μέχρι το τέλος του έτους με πλούσια δώρα, πολλές προσφορές, και φυσικά, νέα προϊόντα.

Μείνετε συντονισμένοι στην ιστοσελίδα μας για να μαθαίνετε πρώτοι τις προσφορές μας και ακολουθήστε μας στο Facebook για να πάρετε μέρος σε διαγωνισμούς με πλούσια δώρα Protem!

ΟΙ ΑΠΟΣΚΕΥΕΣ ΜΑΣ

Ηθική, Ακεραιότητα και Διαχρονικές Αξίες

Δείτε μια σύντομη ιστορική αναδρομή με τους σημαντικούς σταθμούς της τριακονταπενταετούς διαδρομής μας

ΤΟ ΜΥΣΤΙΚΟ ΜΑΣ

Μεθοδική Δουλειά, Ομαδικότητα και πολλή Υπομονή

Μαθαίνουμε από τα λάθη μας αλλά περισσότερο, μαθαίνουμε από τις επιτυχίες μας.

Η ΔΙΑΦΟΡΕΤΙΚΟΤΗΤΑ ΜΑΣ

Πάθος για Καινοτομία

Ο εύκολος δρόμος της αντιγραφής και της μίμησης μάς είναι άγνωστος. Αναπτύξαμε σταδιακά τη δική μας τεχνογνωσία, που την εμπλουτίζουμε διαρκώς με νέες ιδέες και τεχνολογίες. Είμασταν και παραμένουμε ανοιχτοί σε νέες προκλήσεις.

ΟΙ ΟΛΙΣΤΙΚΕΣ ΜΑΣ ΛΥΣΕΙΣ

Εσείς Ακόμη Ψάχνετε πώς να Υλοποιήσετε τις Ιδέες σας;

Ο όμιλος PROTEM είναι 3 εταιρείες σε 1. Με τα 3 τμήματά μας, ηλεκτρονικών – μηχανολογικών – λογισμικών, σχεδιάζουμε, κατασκευάζουμε, εγκαθιστούμε και υποστηρίζουμε λύσεις από το Α έως το Ω για τη Βιομηχανία Σκυροδέματος.

Η ΠΕΡΗΦΑΝΙΑ ΜΑΣ

Επιμένουμε Ελληνικά

Παρά τα εμπόδια και τις τρικλοποδιές του κράτους που πρέπει διαχρονικά να ξεπερνάμε, όλοι οι ευσυνείδητοι και νομοταγείς επιχειρηματίες στη χώρα μας, ακόμη περισσότερο δε οι κατασκευαστές, η PROTEM επιμένει Ελληνικά.

ΟΙ ΣΤΟΧΟΙ ΜΑΣ

Με το βλέμμα στραμμένο στο μέλλον

Η Protem στοχεύει πάντοτε σε ένα καλύτερο και πιο ελπιδοφόρο μέλλον. Η δύναμή μας ήταν και παραμένει το άρτια εκπαιδευμένο ανθρώπινο δυναμικό μας. Η διαρκής ενσωμάτωση νέων επιστημόνων στην κοινότητα, με τις ίδιες αρχές και τη φιλοσοφία της εταιρείας, εγγυώνται μια επιχειρησιακή συνέχεια αντάξια του παρελθόντος.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back