In order to reduce the costs and enable third-parties to buy and install a compact and very reliable automation system to new or existing plants, we now offer you the Auto-Leader 3000P_ECO. Having a tested product and our professional support, it is no longer a challenge, for anybody involved in this business, to create a new profitable activity.

The basic automation kit of the Auto-Leader 3000P_ECO includes the followings:

In order to reduce the costs and enable third-parties to buy and install a compact and very reliable automation system to new or existing plants, we now offer you the Auto-Leader 3000P_ECO. Having a tested product and our professional support, it is no longer a challenge, for anybody involved in this business, to create a new profitable activity.

The basic automation kit of the Auto-Leader 3000P_ECO includes the followings:

A CPU manufactured solely with industrial electronics ensuring uninterrupted operation even in extreme conditions such as high ambient temperatures, humidity, dust environment etc.

Includes:

- Four (4) weighing-batching controllers with high precision, high sample rate and calibration values (log file) memory. With internal calibration switch that can be secured by a wire security seal that is passing through two drilled head screws.

- Two (2) fiber optic bidirectional serial ports for printer and computer connection (for increased protection against electrical surges and lightning strikes).

- Four (4) RS485 ports for communication with the PLC, power meter, humidity meters and remote service support.

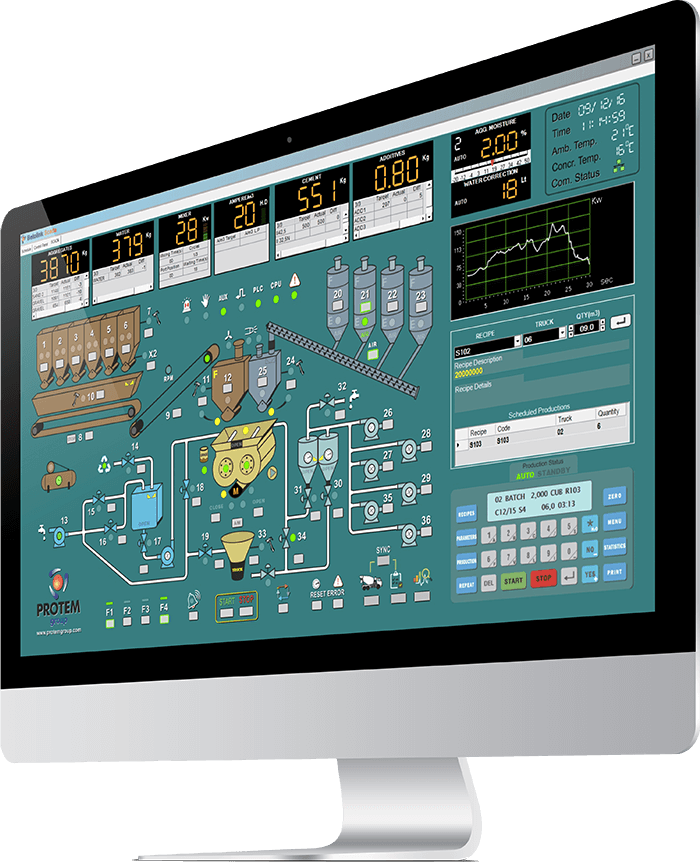

Betolink® SCADA software Lisence

The SCADA software included in Auto-Leader 3000P_ECO, can be installed in a common windows PC and it is used only for production supervision and manual intervention. The PC is not participating in any control sequence. Thus, operation cannot be interrupted by any failure of the PC’s peripherals or the OS, increasing system’s overall reliability.

A PLC is connected through RS485 to the central CPU and acts as an I/O terminal. The PLC has built in input and output cards which are connected to the external input/output modules through premade connector cables (included in the kit).

EXTERNAL INPUT OUTPUT MODULES

A total number of external 32 relay outputs and 32 isolated inputs is offered as standard but can be optionally expanded.

Designed to snap onto a standard DIN rail for installation in a wall mount enclosure, the input /output modules protect and isolate electrically the PLC, making cabling easier. Wiring connections are made using screw terminals positioned along the top and bottom, clearly accessible from the front for easy servicing.

A DIN rail-mounted power meter that offers all the measurement capabilities required to monitor the mixer’s power as well as the concrete slump, which communicates through RS 485 with the CPU.

A dot matrix A3 printer that communicates through fiber optic cable with the CPU to print batch reports and statistics.

A CD that includes the Betolink® SCADA Installation program (including device drivers and plugins) as well as the user’s Manual, the installation Manual and the Electrical Drawings all in printable pdf format.

INTEGRATION WITH Betolink® Pro

Auto-Leader 3000P_ECO is fully integrable with the optional Production Management, Dispatching and Ticketing software Betolink® Pro.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back