PROTEM is an official partner of SICOMA since 2005. We have installed many mixers in our new batching plants or retrofitted existing plants by replacing their mixer. We can safely say that Sicoma Mixers are one of the top value for money proposals on the market while their reliability has been tested and proved by our company.

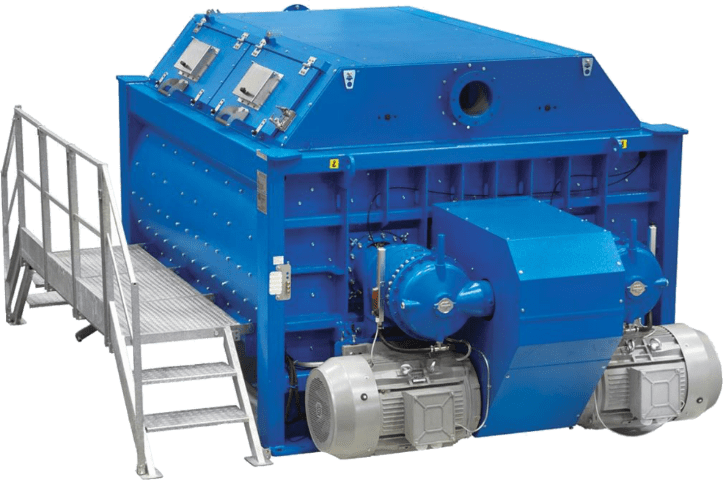

The SICOMA double horizontal shaft mixer will achieve excellent mixing quality in all types of concrete in the most efficient and fastest way with the maximum saving of cement. It will maximize your productivity and reduce your cost per cubic meter. Ideal as a central mixer of high productions from 40 to 360m3 / h.

Extra-rigid tank

The stiffened frame of the tank eliminates the risk of deformation during the transport (also in container) as well as during the full load operation and guarantees the correct planarity of the shafts’ seals. The metal frame for aggregates hopper and the scales can be laid right on the mixer without additional supports.

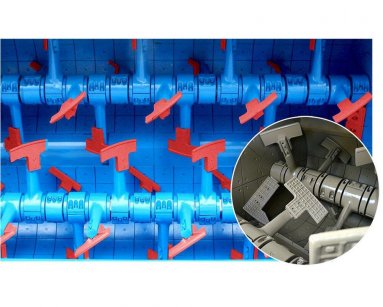

Mixing elements

The mixer tank is lined with interchangeable tiles of cast iron with a minimum hardness of 530HB and 15 mm thickness. The mixing arms, with a low profile to avoid material build up, are made by Spheroidal Cast Iron. The mixing blades are made by Ni-Hard Cast Iron of 530HB minimum hardness. The large number of blades, their position and their orientation guarantees the right combination between the effects of rolling and circulation of the material during the mixing action

Gear boxes

The gearboxes of the mixing group are epicyclical type. The first reduction is carried out by a pulley transmission equipped with a constant-velocity universal joint to keep the shafts synchronized. The low input speed to the gearboxes allows the lubrication oil to work at low thermal load. The connection between the gearbox and the tank is made with the exclusive bell housing. This unique feature gives a better rigidity to the coupling between the gearbox and the tank and makes the assembly and the possible maintenance of the bearings and the seals extremely easy.

Shaft supports and seals

The modular support patented by SICOMA is made with two separate housings. The bearing outside of the mixing tank are immersed in a long-lasting oil bath. The shaft seal, based on the exclusive system of the counter-rotating disks, is lubricated with liquid grease under controlled pressure.

Discharge door

The discharge door is driven by a hydraulic power pack system. The closing of the door is guaranteed by the pressure sensor included in the hydraulic circuit. In case of failure or blackout, a manual pump can be operated for an emergency discharge.

The discharge door has a rubber seal that runs along its full perimeter. The eccentric rotation of the door sector guarantees that the rubber seal is always reached and compressed despite its wear and tear.

Automatic lubrication

The grease needed by the seal to keep the counter-rotating surfaces lubricated is supplied by four (4) independent automatic pumps that keep a constant pressure into the housing. They uniformly and accurately dispense the necessary quantity of grease and guarantee a low grease consumption (less than 0.03kg/h) together with a low contamination of the mixing. A high performance filter removes potential impurities that can enter the circuit when the grease container is refilled.

Alarm box

The mixer is equipped with several sensors: thermal sensors for the motors and for the gearboxes, level gauges for the oil of the gearboxes and for the hydraulic power pack, level and pressure sensors for the automatic lubrication system. Upon request, PROTEM can supply a special electronic controller called «MIXER MIND" to which all sensors and the grease system are connected. The controller informs the operator of the type of each possible malfunction or alarm and signals to the plant automation. Through the controller, the operation of the automatic lubrication can also be programmed according to the particularities of each installation.

Mixer’s cover

The high top cover (500mm) is equipped with two hinged hatches and does not have any post. It allows easy access to the mixer for an accurate cleaning at the end of the shift or for both preventive and unscheduled maintenance resulting in a shorter shutdown time of the plant.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back