WEIGHING PLATFORMS WP3-20-XXL

The WP3-20-XXL platforms have a high accuracy of ±0,5-1,5% FS as long as they are placed on flat and smooth surfaces (industrial floor, asphalt, etc.) and the truck is placed horizontally.

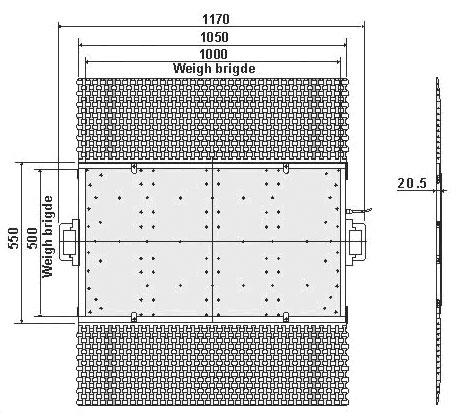

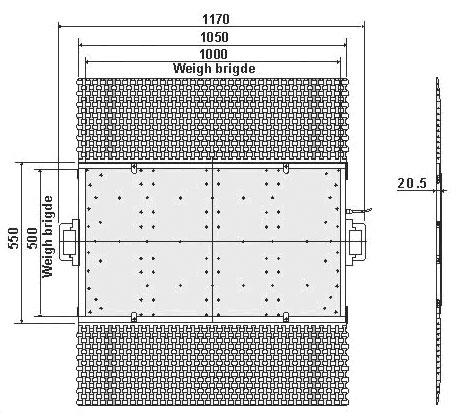

Weighing Pad Size: 1000mm L X 500mm W X 20,5mm H

Construction Material: High strength aluminum

Pad Weight: 46 Kg

Protection Rate: IP66

Leveling track: 0,5 meter each side, 7,5 Kg / 0,5m

Rated Capacity: 20.000 Kg each Platform

Connection: By cable that plugs in the weighing equipment suitcase.

A WIRELESS EDITION OF THE PLATFORMS WITH RECHARGABLE BATTERIES IS ALSO AVAILABLE !

ELECTRONIC WEIGHING EQUIPMENT

An integrated and highly resistant aluminum suitcase that incorporates the necessary weighing electronical equipment. All the equipment is installed and cabled, ready to operate.

Furthermore, inside the suitcase lies a 12V rechargeable battery with a 220V charger as well as plugs for the connection between the platforms and the power supply (for recharging the battery).

Main Technical Features:

- Liquid Crystal dual screen.

- Displaying of time, date, truck license number and serial number of weigh ticket. Battery status with a recharge alarm (for when the power is low).

- Registration of (up to 100) vehicle license numbers, driver & operator names.

- Calculation and displaying of the speed (km/h) as the vehicle passes over.

- Continuous observation of the indication’s value.

- Axle to axle vehicle weighing measurement, without any limitations when it comes to the number of axles.

- Weighing option: Static or Dynamic. A Static measurement results in the vehicle stopping every time one of its axles is directly above the platforms. The operator must then confirm the weighing measurement by pressing one key each time, until the axle weighing is complete. A Dynamic measurement results in the vehicle passing over the platforms while moving slower than 5 Km/h, and the axle weighing will be automatically complete.

- Choose vehicle axle types when dynamically weighing.

- Integrated printer that prints the time/date, License number, weigh bill number, weight per axle & vehicle cross weight. Option to calculate and print the overweight as well as the company name.

- RS232 port for communicating with a PC.

- Great battery life expectancy for weighing all day long without having to charge it.

- The material and the client can be registered when weighing statically.

A WIRELESS EDITION OF THE ELECTRONICAL EQUIPMENT IS ALSO AVAILABLE !

The weighing accuracy of axle weighing cannot be compared to the weighing accuracy of a weighbridge. Nor is selling materials with an axle scale weighing note allowed. It is, however, an easy, fast and budget-friendly weighing solution for material receipt checks, such as aggregates, waste and recyclable materials of small value, where an error of 1-2% is acceptable.

In general, the principles that each and every client of ours much be aware of applied in the weighing accuracy achieved by using our recommended solution are the following:

A1) When the vehicle’s axle weight is ≤20% FS (FS=Full Scale Platform Weighing Capacity, in this case 40T) then the maximum vehicle weighing error’s value is from ± 0.3% FS/ Axle + ± 0.3% RΟ (RΟ=Vehicle Weight).

A2) When the vehicle’s axle weight is ≥20% FS (FS=Full Scale Platform Weighing Capacity, in this case 40T) then the maximum vehicle weighing error’s value is from ± 0.5% F.S + ± 0.3% RΟ (RΟ=Vehicle Weight).

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back