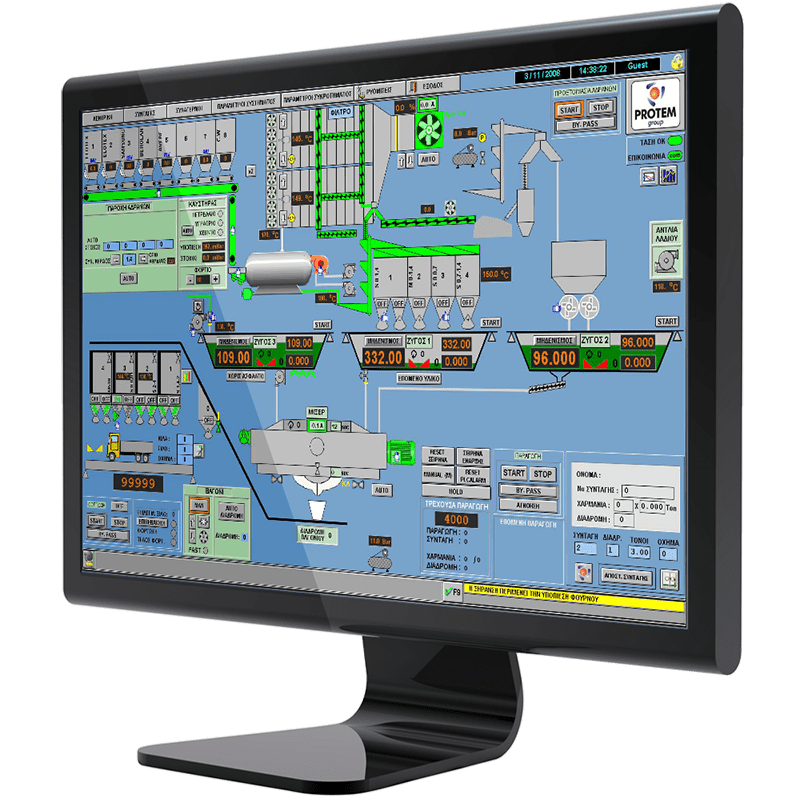

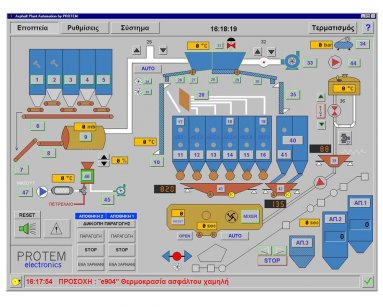

An advanced Asphalt Plant automation system should not only automate the processes of dosing and mixing the raw materials. It should also provide solutions to all the challenging problems the operator faces daily, given that asphalt-mix production is a much more complex procedure than Ready-mix concrete production.

PROTEM asphalt automation provide holistic solutions to the problem of centralized production control, ensuring steady production quality that does not depend on the operator’s skills. In addition the rejections and waste are minimized, resulting in saving valuable resources for the company.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back