- Detailed presentation

The compression testing device is a sturdy, autonomous machine, operating independently on other peripheral systems such as a PC. It is very easy to use, and aimed mainly towards operators with little to no experience when it comes to specimen testing. As a result, the errors that affect the results are nullified and the user’s operator is safeguarded.

Each machine consists of the following:

- Uniform, heavy-duty melded loading frame.

- Hydraulik power pack.

- Hydraulic cylinder equipped with safety limit switch.

- Upper platen Ø 300 mm diameter with self-adjusting ball seating assembly.

- Lower platen Ø 300 mm diameter with engraved concentric circles for easy specimen alignment.

- Distance pieces with a diameter of Ø 205x25 mm, Ø 205x50 mm and Ø 205x80 mm.

- Front and rear protective safety doors. Front door has a safety limit switch.

- Electronic control unit with touch screen display, force adjusting potentiometer, optional thermal printer.

The compression testing device is a sturdy, autonomous machine, operating independently on other peripheral systems such as a PC. It is very easy to use, and aimed mainly towards operators with little to no experience when it comes to specimen testing. As a result, the errors that affect the results are nullified and the user’s operator is safeguarded.

Each machine consists of the following:

- Uniform, heavy-duty melded loading frame.

- Hydraulik power pack.

- Hydraulic cylinder equipped with safety limit switch.

- Upper platen Ø 300 mm diameter with self-adjusting ball seating assembly.

- Lower platen Ø 300 mm diameter with engraved concentric circles for easy specimen alignment.

- Distance pieces with a diameter of Ø 205x25 mm, Ø 205x50 mm and Ø 205x80 mm.

- Front and rear protective safety doors. Front door has a safety limit switch.

- Electronic control unit with touch screen display, force adjusting potentiometer, optional thermal printer.

The heavy-duty welded loading frame is a cost-effective solution that provides the necessary stability for accurate test results over many years of operation.

- 20 Lt oil tank with level and temperature indication.

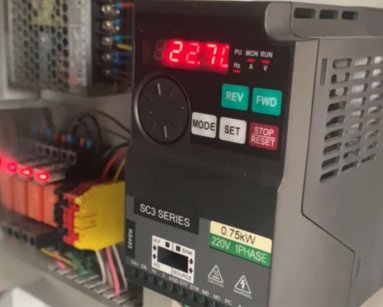

- Two-stage oil pump inside the tank consisting of a) Low pressure gear pump b) High pressure radial piston pump. Thanks to the two-stroke pump, the time until the upper plate reaches the specimen is reduced, and so does the total duration of each test. The high-pressure pump’s revolutions are adjusted by an inverter accordingly to the desired rate of loading.

- The maximum operating pressure is 410 bar, which is the activation limit of the safety valve.

- The motor power of the pump is 380V / 50hz / 0.75Kw.

Hydraulic cylinder with a diameter of Ø250 for the 2.000KN press and Φ320 mm for the 3.000 ΚΝ compression machines, with an active stroke of 50 mm.

A safety limit switch stops the operation of the compression testing machine, in case the piston tends to move out of bounds. In combination with the overpressure valve in the hydraulic pack, maximum safety is provided for the machine and its operator.

PLATENS AND SPACING BLOCKS

Self-leveling upper platen with a diameter of Ø 300 mm Χ 50mm, according to the EN 12390-4 . Made of high-quality steel manufactured with a roughness of 3.2μm, an average hardness of 55 HRC and a flatness of ≤ 5μm.

Bottom platen with the same features as the upper platen plus additionally engraved concentric circles for easy specimen alignment.

Each compression machine is equipped with standard distance pieces Ø 205 x 25 mm, Ø 205 x 50 mm and Ø 205 x 80 mm. These are placed below the lower platen and reduce the distance between the specimen and the upper platen based on specimen type (cube, cylinder, etc.).

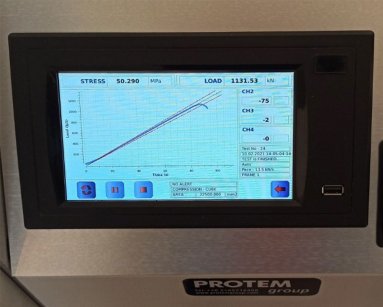

All operations are performed via a Touch screen display, located at the Electronic Unit and Hydraulic Power Pack’s front panel.

- 7’’ touch screen display, 800 x 480 pixel, with 65.535 available colors. Using the integrated PID software the loading speed is regulated automatically, based on user parameters.

- The compression test results can be printed using the optional thermal printer. Uses printing paper with a width of 58mm and a maximum diameter of Ø 50 mm.

- Option to export all compression testing results from the system’s database to a USB stick for transportation and import to a PC.

- The high-pressure pump’s revolutions are adjusted by an inverter accordingly to the desired pace rate.

- The system’s power requirements are 220 V, 50-60 Hz, 1 Ph.

The compression testing machines are very simple to use and allow even unexperienced operators to perform the tests very easily and without mistakes.

As soon as the specimen is aligned with the help of the concentric circles, engraved at the lower platen, the only required actions are:

- Selection of specimen type and rate of loading via the touch screen display (if these parameters have already been set once, this step can be omitted).

- Pressing the “START” button on the touch screen display. By doing so the machine automatically starts a rapid approach until the specimen touches the upper plate and then begins to load the specimen at the selected pace rate (charging speed) and stops when the specimen breaks.

- During each crushing test, the machine automatically adjusts the pace rate, trying to maintain it within the margins (set by the standards). The screen displays the loading chart in real-time along with two indicative curves which are automatically generated by the system signifying the allowed pace rate limits. This way it is clear to the operator if the test has been completed according to the applicable standards. The maximum load in kN and MPa are stored in the controller's memory and are accessible anytime. When the optional thermal printer is installed, the machine automatically prints the compression test results.

- Machine calibration is also made easier than ever before due to the force adjusting potentiometer and the detailed instructions found in the User’s Manual.

- Each press is delivered pre-calibrated and ready for the official calibration, as defined by the regulation which states it must be done at the final installation place.

- A second frame can be installed in the same unit in order to perform different kinds of tests.

- No special maintenance is required apart from preemptive checks and a periodic hydraulic oil replacement.

- Every single compression testing machine is delivered pre-calibrated, ready to operate at the final destination site.

- Detailed User’s operation and maintenance Manual.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back