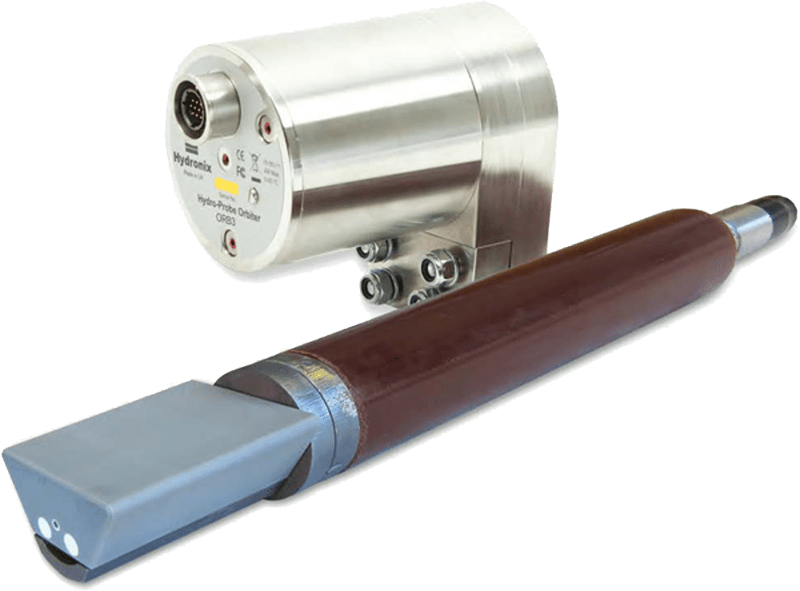

The Hydro-Probe Orbiter is the world's first rotating digital microwave sensor designed specifically to measure moisture and temperature on the inside of a planetary mixer. The sensing head, which can be detached from the rest of the equipment, slices easily through the mix providing accurate moisture measurement of the material in real time. It is ideal for use in cement products.

Hydro-Probe Orbiter

- Quick Overview

Moisture measuring inside the mixer of a concrete production plant for cementitious and precast products is completely mandatory, given that controlling and checking the moisture levels of the final product is perhaps the most important factor as far as quality assurance and raw materials saving is concerned. The most important differences between ready-mix concrete transported by vehicles towards the construction site and ready-mix concrete for cement products have to do with the quantity of water In the mix as well as its homogeneity.

These two factors are very important in Ready-Mix Concrete but not as decisive when it comes to discarding a batch, as the case is with Cement Products. The reason is that every mixing in the precast industry is not eligible for any additional treatment after leaving the mixer. It goes directly to the molds of the products and if the amount of water is not correct, then in the best case scenario the products will be defective. But even if the quantity of water is precisely correct, each batch must be completely homogenized after it exits the mixer so the results are the same batch after batch.

Originally supplied to the concrete industry, the Hydro-Probe Orbiter can also be mounted as a static sensor underneath a bin or above a belt conveyor and is therefore easily adaptable for use in other industries such as sand, aggregates, cereal, animal feed and fish meal.

Moisture measuring inside the mixer of a concrete production plant for cementitious and precast products is completely mandatory, given that controlling and checking the moisture levels of the final product is perhaps the most important factor as far as quality assurance and raw materials saving is concerned. The most important differences between ready-mix concrete transported by vehicles towards the construction site and ready-mix concrete for cement products have to do with the quantity of water In the mix as well as its homogeneity.

These two factors are very important in Ready-Mix Concrete but not as decisive when it comes to discarding a batch, as the case is with Cement Products. The reason is that every mixing in the precast industry is not eligible for any additional treatment after leaving the mixer. It goes directly to the molds of the products and if the amount of water is not correct, then in the best case scenario the products will be defective. But even if the quantity of water is precisely correct, each batch must be completely homogenized after it exits the mixer so the results are the same batch after batch.

Originally supplied to the concrete industry, the Hydro-Probe Orbiter can also be mounted as a static sensor underneath a bin or above a belt conveyor and is therefore easily adaptable for use in other industries such as sand, aggregates, cereal, animal feed and fish meal.

TECHNICAL CHARACTERISTICS

- The Hydro-Probe Orbiter comprises of 2 parts - the head unit which houses the electronics and connections and the sensing arm with a hard wearing ceramic head. Both the sensing arm and the head unit can be easily changed eliminating the need to replace the entire sensor. To extend the wear life of the arm, Hydronix recommends that in all cases the arm is protected from excessive wear by use of an arm guard and protection rings.

- It has powerful digital 32-bit micro controller with 2 analogue outputs (0-10 V or 4-20mA) and an RS485 serial output that is optically isolated and connects through protocol.

- The sensor is equipped with two inputs in order to activate the average calculation of the moisture’s value as well as switching its output between moisture and temperature value. The 'averaging' mode continuously provides the 'average' reading of moisture from the start of reading to any time selected - normally the closing of the hopper door. Averaging, bin empty alarms and signal processing performed internally by sensor.

ADVANTAGES

- Significantly improved measurements due to the usage of a rotating head unit instead of the immobile sensors at the bottom of the mixer.

- Fast and steady moisture measurements that are not affected by the mixing paddles.

- The electronic circuits are not incorporated to the measuring surface which is located at the end of a special arm guard that can be replaced individually.

- Installation is a piece of cake, without needing to puncture through the cell and the mixer’s coating.

INSTALLATION

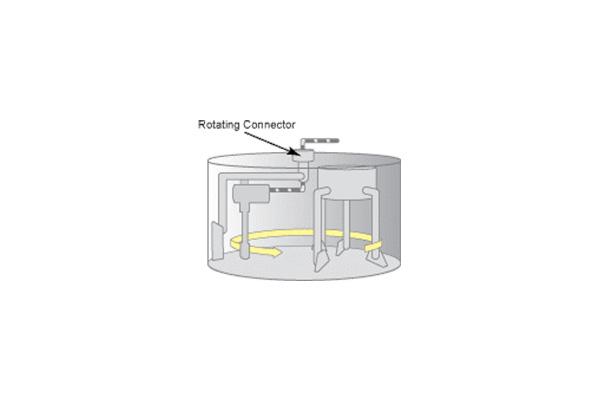

Unlike other sensors which are positioned so that the material flows over the sensor face, the Hydro-Probe Orbiter is placed on top of the rotating arm of the mixer’s scraper. As a result its heading is designed to move rapidly through the mix, in a distance of approximately 50mm above the bottom, providing a very fast response to changes in moisture.

The Hydro-Probe Orbiter may be easily mounted in static pan mixers such as Turbo or Planetary mixers when used with a Rotating Connector. It is fitted to the top cover of the mixer and provides a simple way of connecting the plant wiring outside of the mixer to the sensor wiring within the mixer to allow all relevant signals from the sensor to be accessed.

Below are listed some typical Hydro-Mix installation examples

RESISTANCE TO CORROSION

The sensing arm is is supplied with protective rings of hardened steel. It is as a result protected from the corrosion caused by the Ready-Mix Concrete. Apart from the sensing arm, the sensing surface is also made of hardened steel, and when damaged it can be replaced individually causing only minimal disruption to production.

Open to new challenges

Do you have any idea of cooperation, you believe that our know-how can be adapted to your own field?

Do you have a special project and are looking for suitable partners to implement it? We are open to new opportunities...

Connect with us

Do you prefer live communication? So do we!

We'd love to speak with you.

Contact us

Get support

Do you have any technical questions?

Our experienced engineers will gladly discuss with you.

Technical Support

Stay updated

Are you interested in receiving updates

about our new products and offers?

Subscribe

Protem Group S.A.

3, 35th Str., 133 41 Industrial Park

Ano Liossia / Athens, Greece

info@protem.gr

Τ. +30 210 5716500

F. +30 210 5710008

GCR No: 7633901000

The Company

Contact

Company News

Legal Information

1989 - 2024

Φέτος έχουμε γενέθλια! Τον Ιούλιο κλείνουμε τα 35!

35 χρόνια σκληρή δουλειά με αγάπη, αφοσίωση και με σημαντικές επιτυχίες! 35 δημιουργικά χρόνια. Θα τα γιορτάζουμε μαζί σας μέχρι το τέλος του έτους με πλούσια δώρα, πολλές προσφορές, και φυσικά, νέα προϊόντα.

Μείνετε συντονισμένοι στην ιστοσελίδα μας για να μαθαίνετε πρώτοι τις προσφορές μας και ακολουθήστε μας στο Facebook για να πάρετε μέρος σε διαγωνισμούς με πλούσια δώρα Protem!

ΟΙ ΑΠΟΣΚΕΥΕΣ ΜΑΣ

Ηθική, Ακεραιότητα και Διαχρονικές Αξίες

Δείτε μια σύντομη ιστορική αναδρομή με τους σημαντικούς σταθμούς της τριακονταπενταετούς διαδρομής μας

ΤΟ ΜΥΣΤΙΚΟ ΜΑΣ

Μεθοδική Δουλειά, Ομαδικότητα και πολλή Υπομονή

Μαθαίνουμε από τα λάθη μας αλλά περισσότερο, μαθαίνουμε από τις επιτυχίες μας.

Η ΔΙΑΦΟΡΕΤΙΚΟΤΗΤΑ ΜΑΣ

Πάθος για Καινοτομία

Ο εύκολος δρόμος της αντιγραφής και της μίμησης μάς είναι άγνωστος. Αναπτύξαμε σταδιακά τη δική μας τεχνογνωσία, που την εμπλουτίζουμε διαρκώς με νέες ιδέες και τεχνολογίες. Είμασταν και παραμένουμε ανοιχτοί σε νέες προκλήσεις.

ΟΙ ΟΛΙΣΤΙΚΕΣ ΜΑΣ ΛΥΣΕΙΣ

Εσείς Ακόμη Ψάχνετε πώς να Υλοποιήσετε τις Ιδέες σας;

Ο όμιλος PROTEM είναι 3 εταιρείες σε 1. Με τα 3 τμήματά μας, ηλεκτρονικών – μηχανολογικών – λογισμικών, σχεδιάζουμε, κατασκευάζουμε, εγκαθιστούμε και υποστηρίζουμε λύσεις από το Α έως το Ω για τη Βιομηχανία Σκυροδέματος.

Η ΠΕΡΗΦΑΝΙΑ ΜΑΣ

Επιμένουμε Ελληνικά

Παρά τα εμπόδια και τις τρικλοποδιές του κράτους που πρέπει διαχρονικά να ξεπερνάμε, όλοι οι ευσυνείδητοι και νομοταγείς επιχειρηματίες στη χώρα μας, ακόμη περισσότερο δε οι κατασκευαστές, η PROTEM επιμένει Ελληνικά.

ΟΙ ΣΤΟΧΟΙ ΜΑΣ

Με το βλέμμα στραμμένο στο μέλλον

Η Protem στοχεύει πάντοτε σε ένα καλύτερο και πιο ελπιδοφόρο μέλλον. Η δύναμή μας ήταν και παραμένει το άρτια εκπαιδευμένο ανθρώπινο δυναμικό μας. Η διαρκής ενσωμάτωση νέων επιστημόνων στην κοινότητα, με τις ίδιες αρχές και τη φιλοσοφία της εταιρείας, εγγυώνται μια επιχειρησιακή συνέχεια αντάξια του παρελθόντος.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back