The 3DLevelScanner provides a scaled 4–20 mA output that can represent either the product or headroom volume. A digital HART communication signal superimposed on the 4–20 mA cable can enable two-way field communications, allowing for additional information beyond the normal process variable to be communicated to the 3DLevel Manager software. Up to 64 scanners can be directly connected via a RS-485 network to a PC running the 3DLevel Manager software or to multiple computers on a network using TCP/IP via a RS-485 network. Alternatively, a Modbus implementation can utilize the RS-485 network to send data.

The 3DLevelScanner provides a scaled 4–20 mA output that can represent either the product or headroom volume. A digital HART communication signal superimposed on the 4–20 mA cable can enable two-way field communications, allowing for additional information beyond the normal process variable to be communicated to the 3DLevel Manager software. Up to 64 scanners can be directly connected via a RS-485 network to a PC running the 3DLevel Manager software or to multiple computers on a network using TCP/IP via a RS-485 network. Alternatively, a Modbus implementation can utilize the RS-485 network to send data.

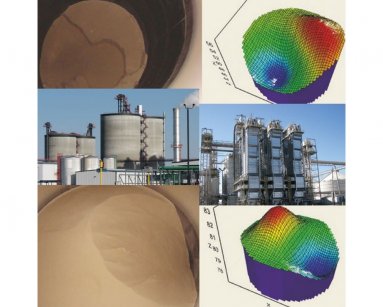

The 3DLevelScanner uses a very low frequency acoustical signal to penetrate dust and take measurements which are determined by how long the signal takes to “travel to” solid or powder material and “return to” the device. These very low frequency acoustical signals are able to penetrate suspended dust, unlike other technologies whose signals become “confused” when attempting to take measurements in dusty environments.

Unlike single point devices, it works by measuring multiple points within the bin. The acoustical signals, combined with a non-stick material, prevent material from adhering to the internal workings of the device ensuring long-term reliable performance. The 3DLevelScanner is self-cleaning, offering very low maintenance in even the dustiest environments.

The 3DLevelScanner is a non-contact device, so it is ideal for food processing, pharmaceuticals, or chemicals where contact with the material being measured must be avoided. It can be applied to any kind of silo, tank, warehouse and open bin or pile and it also detects cone up, cone down and sidewall buildup.

The system is ideal for pellets, granulars, powders and most other bulk solids. It is also suitable for “sticky” materials whose level needs to be monitored, but the material could cause problems by adhering to the measurement device. It also avoids situations such as broken or buried cables, which can cause maintenance problems and result in downtime and periods when no measurements can be taken.

To name a few, 3DLevelScanner can be applied to the following materials:

- Cement

- Aggregates

- Flying ash, Gypsum

- Ethanol and Bioenergy

- Pulp, Paper and Wood Pellets

- Mining and Metals

- Plastics and Chemical Processing

- Petrochemical Products

- Taking measurements from multiple points versus from a single point takes into account variations that can occur on material surfaces

- Continuous and non-contact material measurement, making the system ideal for applications where contact with the material being measured must be avoided.

- Measures and accurately maps the topography on the surface of powders or other bulky solids.

- Detects cone up, cone down and sidewall buildup.

- Operates perfectly even in extremely dusty environments using the acoustics-based technology, as the low-frequency signals penetrate dust without ever becoming “confused”.

- No need for special calibration or adjustment. The system consumes very little power, making it cost-effective to operate.

- The system communicates via 4-20/HART, Modbus RTU, TCP/IP and RS-485

- Measurement range is up to 200’.

- The acoustics-based technology helps keep the transducers clean, requiring only periodic maintenance (every six months) in even extremely dusty environments.

- Up to 64 scanners may be directly connected to an RS-485 network at the same time.

There are three available models of the 3DLevelScanner system, known as “S”, “M” & “MV”, all of which are accompanied by the exclusive 3DLevelManager Software. Each of those has its own specifications, in order for you to select that which better suits your needs:

Model “S”

Bin Height: Up to 200’ tall

Bin Diameter: Up to 14’ diameter

Beam Angle: 30°

Output Data: Average distance

Best Application: Tall, narrow bins with little to no corrugation

3D Visualization: No

Model “M”

Bin Height: Up to 200’ tall

Bin Diameter: Up to 45’ diameter

Beam Angle: 70°

Output Data: Estimated volume plus minimum, maximum and average distance

Best Application: Wide bins, taller than they are wide

3D Visualization: No

Model “MV”

Bin Height: Up to 200’ tall

Bin Diameter: Up to 45’ diameter

Beam Angle: 70°

Output Data: 3D Visualization, Estimated volume plus minimum, maximum and average distance

Best Application: Wide bins, taller than they are wide

3D Visualization: Yes

TECHNICAL CHARACTERISTICS

- Measurement Range: Up to 200’

- Operating Temperature: Ranging from -40°C to +85°C

- Operational Pressure: Ranging from -0.2 to 3 bar (-2.9 to 14.5 psi)

- Output: Scaled 4–20 mA/HART/RS-485/Modbus

- Signal Frequency: 3KHz to 10KHz

- Power supply: 20 to 32 VDC

- Power consumption: Max 1.5 W @ 24 VDC

- Certifications & Approvals: CFM Intrinsically Safe Class I, II, Division I, Groups C, D, E, F, G (U.S.A. & Canada)

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back