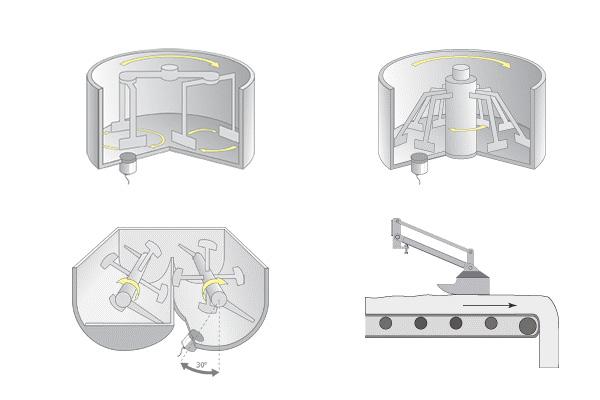

The Hydro-Mix is a rugged, flush mounted microwave moisture measurement sensor for mixers and conveyors in process control environments. Designed by Hydronix to be installed in the turbulent environment of a mixer, the Hydro-Mix features integral signal processing and is easily connected to any control system. The sensor measures at 25 times per second which enables rapid response to any changes in moisture content, including the determination of homogeneity.

The Hydro-Mix sensor offers a choice of measurement modes for optimising the sensor performance for sand, aggregates, concrete and other similar materials. The sensor is designed to be fitted flush within a mixer, screw conveyor or in a chute. For conveyor belt applications, the Hydro-Mix sensor is installed using the Hydro-Skid pantograph arm enabling the sensor to ride over the surface of the flowing material.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back