The SmartBob2 system works by utilizing the simple, yet innovative principle of measuring the distance of the material from the roof of the silo or the reservoir in which it is stored. The measurements are read by a computer running the eBob software and converted into weight, volume, and percent full for each silo. The software can manage up to 100 silos simultaneously.

The SmartBob2 system works by utilizing the simple, yet innovative principle of measuring the distance of the material from the roof of the silo or the reservoir in which it is stored. The measurements are read by a computer running the eBob software and converted into weight, volume, and percent full for each silo. The software can manage up to 100 silos simultaneously.

When a SmartBob2 positioned on the top of a vessel is asked to take a measurement, a heavy-duty motor releases a strong, stainless steel aircraft cable from the supply pulley and a weighted sensor probe quickly descends to the surface of the material.

During the descent, the SmartBob2 measures the cable dispensed by counting pulses with a high resolution micro-controlled optical sensing system. When the sensor probe touches the material surface, pulses are momentarily stopped and measurement information is transmitted.

The absence of pulses also causes the motor to reverse and retract the sensor probe. A second confirming measurement is taken as the probe retracts and is compared to the descend measurement

As the probe is retracted, motor torque is automatically reduced during the last 40cm of the retract cycle resulting in a “soft retract seating,” which extends the life of the SmartBob2 and ensures proper cable spooling.

The SmartBob2 is applicable to any silo or storage space. Whether it is a measurement of bulk powder, coarse solids, liquids, slurries or even sediments under the surface of a liquid, due to the numerous weight sensors available, the SmartBob2 is the most reliable and cost-effective solution.

Indicatively, below is a list of materials to which the SmartBob2 inventory measurement system can be applied:

- Cement

- Aggregate materials

- Bulk fines and coarse grains, such as lime, ash, gypsum, etc.

- Plastics and Chemicals

- Coal

- Animal feed

- Pharmaceutical products

- Food, Seeds & Grain

- Fast and simple installation that can be completed by the customer. Not a single adjustment is required on either the silo or the tank, except an Φ83 mm hole on top.

- No calibration or adjustment is required. The dedicated SmartBob2 controller measures the level accurately and the rest is all done using a PC-based software.

- Designed for demanding applications, the SmartBob2 is suited for rugged and dusty environments. It has a built-in system in order to automatically clean the wire rope as well as prevent the insertion of dust from its passage hole.

- Dual-compartment, so that the mechanical compartment is completely separated from the fully-sealed electronic compartment. This protects the electronics from dust, debris, condensation and other contaminants, providing exceptional reliability and significantly extending the life expectancy of the unit.

- 5th Generation eBob software installed on any computer, allowing you to simultaneously check the inventory status on all your silos with remote access control.

- Cost-effective, since a single eBob software license allows you to manage up to 100 different SmartBob2 devices.

- Automatic alarms and notification alerts via e-mail if critical inventory levels are reached.

- Minimal ongoing operational and maintenance cost.

- Every single silo can be connected to an RS-485 network using a single cable at a cabling distance of up to 1.200m.

- A wireless communication option is available, thus eliminating the usage of the RS-485 communication cable from the control source on the ground to the first SmartBob2 sensor in multiple groups of vessels.

- A large variety of external wireless options is available, such as spiked sensor probes, floating spheres and steel cones, so that the system applies perfectly to any kind of application.

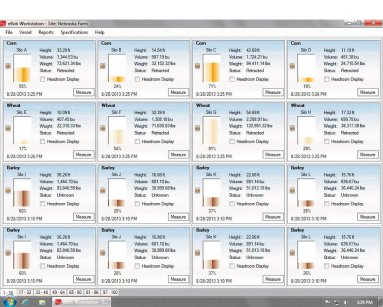

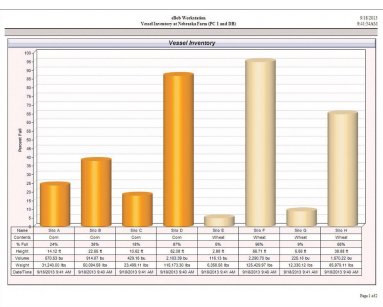

The eBob software receives the signal from the SmartBob2 sensors and converts it, through advanced algorithms, into measurement data which is then exported to the users. It serves to monitor and control up to 100 silos with BinMaster sensors installed. It manages inventory levels, automatically scans and graphically displays all silos, level, weight, percent full, etc.

Using the eBob software, the special shape of your silo or tank is not a problem when it comes to accuracy. It is possible to register any silo geometry and thus automatically calculate the volume and weight of the contents. It is a network software accessible from all computers connected to the company's network and has an open SQL database. The price for the software is identical, whether it is used for 1 or 100 silos.

TECHNICAL CHARACTERISTICS

- Power Requirements: 115/230 VAC 50/60 Hz

- Ambient Temp: -40°F to +185°F (-40°C to +85°C)

- Process Temp: Up to 500°F (260°C)

- Measurement Range: Up to 55m (150’)

- Measurement Rate: 0.6m/sec

- Accuracy: ± 0.25% distance measurement accuracy

- Mounting: 3” hole – 8” NPT mounting flange

- Enclosure: Molded polycarbonate, resistant to corrosion

- Approvals & Certifications: Listed for Class II, Groups E, F, & G Hazardous Locations

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back