We offer you the ability to convert your existing compression testing machine in order to be in conformity with the EN 12390-4 requirements. By keeping your old press frame and installing our kit, you will able to perform the crushes of your specimens fully automatically at the preset load rate while the accuracy of your strength results (MPa) will increased to the highest possible level.

Retrofitting of an Old Concrete Press

PROTEM has developed an integrated solution for upgrading old compression testing machines that can be applied to almost any type of machine.

With our experience, we propose the complete replacement of the old hydraulic pack of your press as well as all the electronic measuring equipment. We will only keep the loading frame and all its accessories (cylinder, platen etc.) intact, provided of course that they are working properly.

The proposed solution consists of a self-contained compact hydraulic power pack unit that feeds the cylinder of the old press and an electronic control panel that fully controls the press.

PROTEM has developed an integrated solution for upgrading old compression testing machines that can be applied to almost any type of machine.

With our experience, we propose the complete replacement of the old hydraulic pack of your press as well as all the electronic measuring equipment. We will only keep the loading frame and all its accessories (cylinder, platen etc.) intact, provided of course that they are working properly.

The proposed solution consists of a self-contained compact hydraulic power pack unit that feeds the cylinder of the old press and an electronic control panel that fully controls the press.

HYDRAULIC POWER PACK

It is a compact construction (all in one) with built-in electronic control panel. It features rollers and a handle for easy movement and includes:

- 30 liter oil tank with level and temperature indication.

- Two-stage oil pump inside the tank consisting of a) Low pressure gear pump b) High pressure radial piston pump. Thanks to the two-stroke pump the time until the specimen reaches the upper plate is reduced and the total duration of each test is reduced accordingly. The high-pressure pump’s revolutions are adjusted by an inverter accordingly to the desired rate of loading.

- The maximum operating pressure is 700 bar, which is the activation limit of the safety valve.

- Distribution block controlling the oil flow provided by the two stage pump. It incorporates a safety valve (in case of overpressure) and a socket for the pressure sensor.

- High accuracy pressure transducer 0,05% FS made by the Swiss company KELLER. This is a digital sensor that communicates with the PLC via RS485, bypassing the usage of analog converters (A/D) that usually distort the measurements. The sensor measures the ambient as well as the oil temperature, and automatically compensates for temperature variations providing the same accuracy in any ambient temperature conditions.

- The motor power of the pump is 380V / 50hz / 0.75Kw.

- External oil filter for retention of foreign particles that may be present in the hydraulic circuit (very common in old presses).

ELECTRONIC CONTROL UNIT

It is steel enclosure, IP54, with a front access door, mounted on a base in the hydraulic tank and includes:

- Telemecanique PLC with PROTEM’s special PID software to automatically adjust the loading rate.

- Telemecanique or Fuji inverter. The loading rate is controlled by changing the pump motor rotation speed.

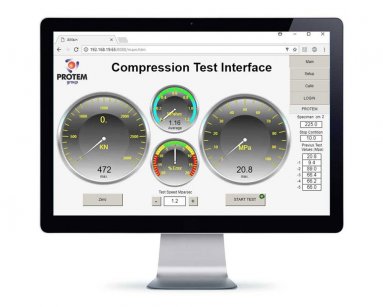

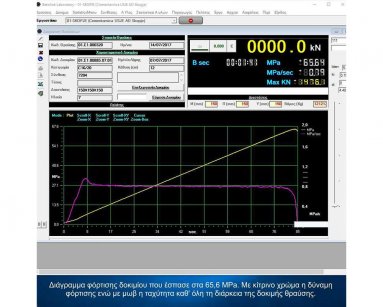

- PROTEM’s SCADA software for monitoring and controlling the machine, specimen crushing and calibration. No installation is required because it is a web application running through the browser on any device (PC, laptop, Tablet or smartphone).

- Plug & Play ready to be connected to PROTEM’s optional Laboratory Management Software, Betolink® Laboratory.

- START button as well as EMERGENCY STOP button.

ADVANTAGES OF OUR SOLUTION

- Not having to buy a new press saves you a lot of funds.

- Make your tests by automatically adjusting and maintaining the rate of loading (constant speed) as required by the regulations (EN 12390-4).

- Increase the precision of your test results as our measurement and recording system is much more accurate than any existing system. All of the presses we upgrade can be classified as Class 1 according to EN ISO 7500-1 after calibration by certified bodies (customer's responsibility).

- If it is required to replace the loading frame in the future, whether because it may be spoiled and repairing it is unprofitable or because you may want to increase its capacity (e.g. from 2.000 to 3.000KN), it can easily be done by keeping our upgrading kit the same and replacing only the frame with a new one by PROTEM or any other manufacturer.

- Your press will become much simpler to use and even inexperienced operators can perform tests more easily and faster than they do today.

- The noise levels in the press operation room will be greatly reduced (<60 dB).

- Regular calibration of the press will be made much easier and with smaller errors thanks to the special calibration routine that incorporates PROTEM's SCADA software.

- Your technical support will now be provided by PROTEM.

APPLICATION

- Our solution applies to almost any type of concrete compression testing machine available in the market.

- Whether you have an old mechanical press or a newer electronical one that does not confirm with the EN 12390-4 standard, our solution can fully modernize your press and will also offers you the ability to connect it to our Laboratory Management software.

Open to new challenges

Do you have any idea of cooperation, you believe that our know-how can be adapted to your own field?

Do you have a special project and are looking for suitable partners to implement it? We are open to new opportunities...

Connect with us

Do you prefer live communication? So do we!

We'd love to speak with you.

Contact us

Get support

Do you have any technical questions?

Our experienced engineers will gladly discuss with you.

Technical Support

Stay updated

Are you interested in receiving updates

about our new products and offers?

Subscribe

Protem Group S.A.

3, 35th Str., 133 41 Industrial Park

Ano Liossia / Athens, Greece

info@protem.gr

Τ. +30 210 5716500

F. +30 210 5710008

GCR No: 7633901000

The Company

Contact

Company News

Legal Information

1989 - 2024

Φέτος έχουμε γενέθλια! Τον Ιούλιο κλείνουμε τα 35!

35 χρόνια σκληρή δουλειά με αγάπη, αφοσίωση και με σημαντικές επιτυχίες! 35 δημιουργικά χρόνια. Θα τα γιορτάζουμε μαζί σας μέχρι το τέλος του έτους με πλούσια δώρα, πολλές προσφορές, και φυσικά, νέα προϊόντα.

Μείνετε συντονισμένοι στην ιστοσελίδα μας για να μαθαίνετε πρώτοι τις προσφορές μας και ακολουθήστε μας στο Facebook για να πάρετε μέρος σε διαγωνισμούς με πλούσια δώρα Protem!

ΟΙ ΑΠΟΣΚΕΥΕΣ ΜΑΣ

Ηθική, Ακεραιότητα και Διαχρονικές Αξίες

Δείτε μια σύντομη ιστορική αναδρομή με τους σημαντικούς σταθμούς της τριακονταπενταετούς διαδρομής μας

ΤΟ ΜΥΣΤΙΚΟ ΜΑΣ

Μεθοδική Δουλειά, Ομαδικότητα και πολλή Υπομονή

Μαθαίνουμε από τα λάθη μας αλλά περισσότερο, μαθαίνουμε από τις επιτυχίες μας.

Η ΔΙΑΦΟΡΕΤΙΚΟΤΗΤΑ ΜΑΣ

Πάθος για Καινοτομία

Ο εύκολος δρόμος της αντιγραφής και της μίμησης μάς είναι άγνωστος. Αναπτύξαμε σταδιακά τη δική μας τεχνογνωσία, που την εμπλουτίζουμε διαρκώς με νέες ιδέες και τεχνολογίες. Είμασταν και παραμένουμε ανοιχτοί σε νέες προκλήσεις.

ΟΙ ΟΛΙΣΤΙΚΕΣ ΜΑΣ ΛΥΣΕΙΣ

Εσείς Ακόμη Ψάχνετε πώς να Υλοποιήσετε τις Ιδέες σας;

Ο όμιλος PROTEM είναι 3 εταιρείες σε 1. Με τα 3 τμήματά μας, ηλεκτρονικών – μηχανολογικών – λογισμικών, σχεδιάζουμε, κατασκευάζουμε, εγκαθιστούμε και υποστηρίζουμε λύσεις από το Α έως το Ω για τη Βιομηχανία Σκυροδέματος.

Η ΠΕΡΗΦΑΝΙΑ ΜΑΣ

Επιμένουμε Ελληνικά

Παρά τα εμπόδια και τις τρικλοποδιές του κράτους που πρέπει διαχρονικά να ξεπερνάμε, όλοι οι ευσυνείδητοι και νομοταγείς επιχειρηματίες στη χώρα μας, ακόμη περισσότερο δε οι κατασκευαστές, η PROTEM επιμένει Ελληνικά.

ΟΙ ΣΤΟΧΟΙ ΜΑΣ

Με το βλέμμα στραμμένο στο μέλλον

Η Protem στοχεύει πάντοτε σε ένα καλύτερο και πιο ελπιδοφόρο μέλλον. Η δύναμή μας ήταν και παραμένει το άρτια εκπαιδευμένο ανθρώπινο δυναμικό μας. Η διαρκής ενσωμάτωση νέων επιστημόνων στην κοινότητα, με τις ίδιες αρχές και τη φιλοσοφία της εταιρείας, εγγυώνται μια επιχειρησιακή συνέχεια αντάξια του παρελθόντος.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back