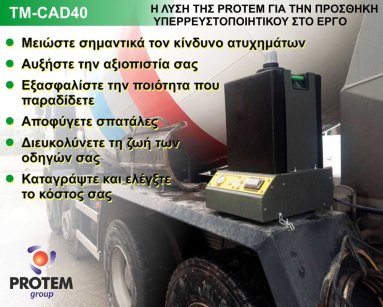

The system TM-CAD40 is a brand-new, smart device designed and manufactured exclusively by PROTEM. It is installed on a mixer truck and used for measuring the additives amount dispensed on site.

It is an autonomous device, compact in size and ergonomically designed to be easily installed on concrete mixer trucks. It does not protrude from the vehicle and can be very quickly removed & reinstalled for service purposes or in case of needs to be swapped on another mixer truck. The daily use of the device by the driver is completely simplified, without any risk of an accident. No need any more for the driver to access the drum entrance holding a canister in order to discharge the superplasticizer in his load. Even the refueling of its tank is done easily from the road level.

The additive is dosed automatically by the device with an accuracy of ± 2% and a resolution of 20 ml. The system is CE certified and does not require special installation permission because it does not operate under pressure, like other systems in the market.

User Login

User Login

Απομακρυσμένη Τεχνική Υποστήριξη

Απομακρυσμένη Τεχνική Υποστήριξη Whatsapp

Whatsapp Email

Email Call back

Call back